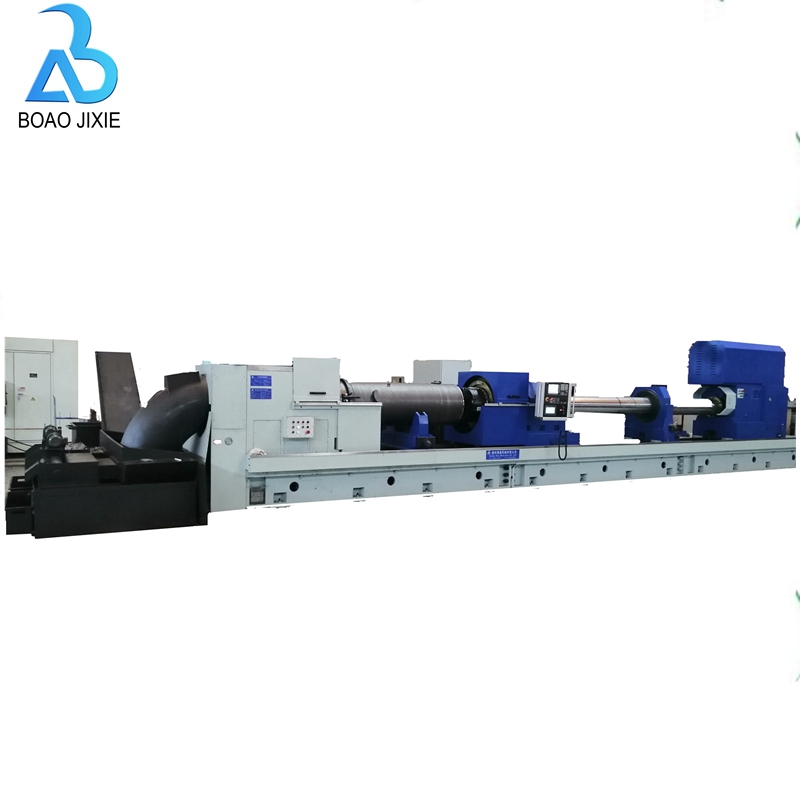

TGK 36 Deep Hole CNC Advanced Boring & Grinding Machine

Makina Khalidwe

TGK25 mndandanda wa CNC skiving & rolling machine chida utenga njira yosinthira ya workpiece yokhazikika ndi chakudya chozungulira cha chida.Chida cha makina chimatha kuzindikira kusangalatsa, kukwapula ndi kugubuduza kwa mabowo amkati mwazogwirira ntchito, njira yopangira ndiyosavuta, ndipo zinthu zomwe zimakonzedwa ndizolondola kwambiri.Ubwino waukulu wa chida ichi makina ndi mkulu processing dzuwa, ntchito khola, ndi dzuwa ndi 5 mpaka 10 nthawi zachikhalidwe zakuya dzenje wotopetsa makina ndi honing makina;digiri ya kuwongolera mwanzeru ndi yayikulu, ndipo kuwongolera kwa digito ndikuwunika kwa lamulo lililonse lachida cha makina ndi losavuta komanso losavuta.zosavuta kugwira ntchito.

Zida zamakina za TGK25 zili ndi zida zowongolera manambala za Nokia 828D;bokosi la spindle limayendetsedwa ndi injini ya AC servo yokhala ndi liwiro lopanda masitepe, ndipo chotengera cha spindle chimatenga ma bere olondola kwambiri ndikulondola kozungulira kwambiri.Bokosi la chakudya limatenga AC servo mota yokhala ndi liwiro lopanda mayendedwe;ili ndi zomangira zolondola kwambiri za mpira kuti zizindikire molondola kwambiri komanso chakudya chokhazikika cha bokosi la spindle.CNC scraping and rolling machine ili ndi chida chowonjezera chodziwikiratu chodziwikiratu komanso chowongolera, chida chapadera cha pneumatic ndi hydraulic retraction system, chogwirira ntchito chimakhazikika, ndipo kutulutsa kwakunja kwa malekezero awiri a silinda kumagwiritsidwa ntchito ngati. maziko oyika.Bowo lamkati limamalizidwa ndi nthawi imodzi yotopetsa, kukanda ndi kugudubuza.Zidazi siziyenera kukhala zoyenera kugwiritsa ntchito ECOROOL hydraulic scraping head, komanso zoyenera kugwiritsa ntchito mutu wa pneumatic scraping.Pulojekitiyi ndi pulojekiti ya turnkey.Zidazi ndizoyenera kwambiri pokonza ma silinda osiyanasiyana a hydraulic, masilindala ndi zida zina zapaipi zolondola.

Makina a Parameters

| NO | Zinthu | Kufotokozera |

| 1 | Processing Inner Diameter Range | Φ60-360mm |

| 2 | Processing Depth Range | 1000mm-12000m |

| 3 | Machine Guideway Width | 650 mm |

| 4 | Spindle Center urefu | 450 mm |

| 5 | Kuthamanga kwa Spindle, Maphunziro | 60-1000rpm, magiya 4, opanda stepless |

| 6 | Main Motor | 45/60/75KW, AC servo mota |

| 7 | Kudyetsa Speed Range | 5-3000mm/mphindi (popanda sitepe) |

| 8 | Liwiro Loyenda Mwachangu | 3000/6000mm / min |

| 9 | Fixture Clamping Range | Φ120-450mm |

| 10 | Kudyetsa motere | 48Nm (Siemens AC servo motor) |

| 11 | Coolant System Motors | N=7.5kw 11kw 15kw |

| 13 | Coolant System Rated Pressure | 2.5MPa |

| 14 | Coolant System Flow | 200L/mphindi, 200L/mphindi, 200L/mphindi (maseti 3) |

| 15 | Kuthamanga kwa Hydraulic System | 7 MPa |

| 16 | Kuthamanga kwa Air | ≥0.4MPa |

| 17 | Control System | Siemens |

| 18 | Magetsi | 380V.50HZ, 3 Phase (Sinthani Mwamakonda Anu) |

| 19 | Muyezo wa makina | L*2400*2100*( L*W*H) |

Zida Zofunika Zamakina

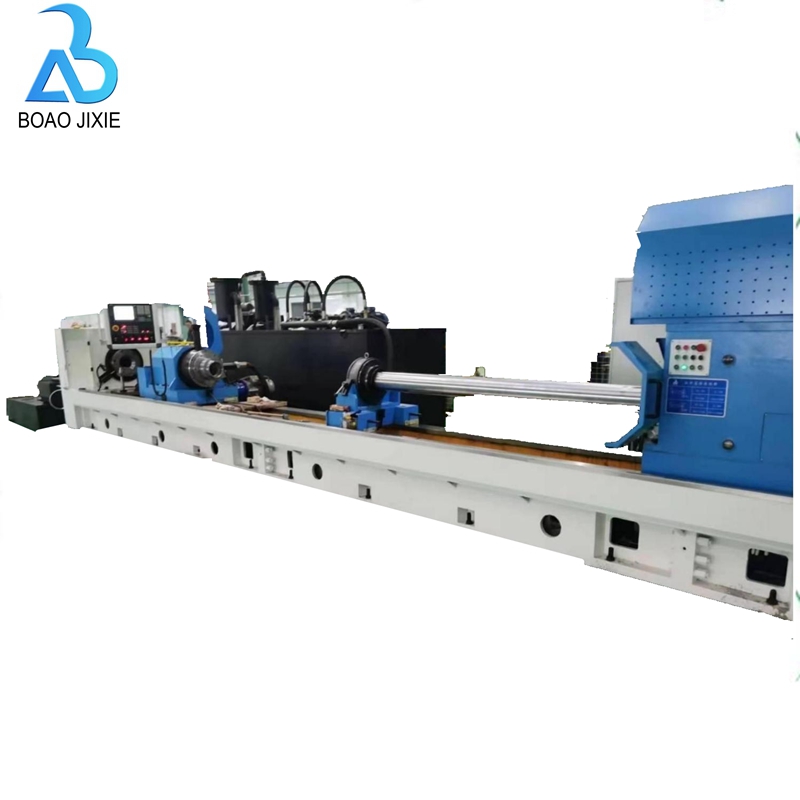

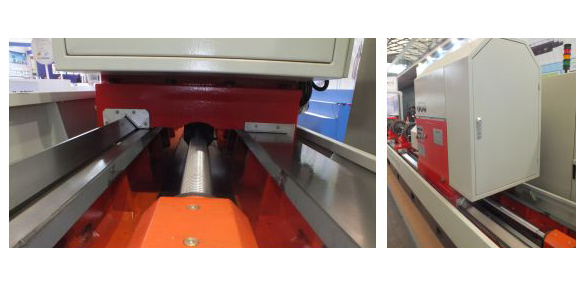

1. Bedi la Makina

Bedi limatenga mawonekedwe a njanji ya rectangular lathyathyathya, ndipo m'lifupi mwake ndi 650mm.Thupi la bedi ndilo gawo lalikulu la chida cha makina, ndipo kukhazikika kwake kumakhudza mwachindunji ntchito yogwira ntchito ndi kulondola kwa makina onse.Choncho, bedi la chida ichi cha makina amapangidwa ndi mchenga wa resin ndikuponyedwa ndi chitsulo chapamwamba kwambiri cha HT300.Ili ndi mawonekedwe abwino komanso mphamvu.Kapangidwe ka nthiti ndi koyenera.Mbali yakunja ya bedi imaponyedwa ndi groove yobwerera kumbuyo, ndipo chivundikiro chotetezera chimayikidwa panja, chomwe chimakhala ndi mawonekedwe abwino otetezera komanso osataya mafuta.Imatha kutolera bwino madzimadzi odula ndikubwezeretsanso pamodzi kuti agwiritse ntchito mobwerezabwereza.Bedi limatenga kamangidwe kagawanika, ndipo njanji yowongolera imatengera kuzimitsa pafupipafupi kwapakatikati (kuuma kosachepera HRC50, kuumitsa kwakuya kosachepera 3mm) ndiyeno kukupera, zomwe zimapangitsa chida cha makina kukhala ndi kukana kwabwino kwa kuvala komanso kusungidwa bwino.

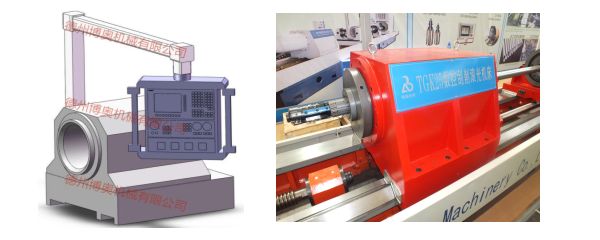

2. Wotopetsa Ndodo Drive Bokosi

Bokosi la bar lotopetsa ndi gawo lophatikizika loponyera ndipo limayikidwa pa pallet ya chakudya.Spindle imayendetsedwa ndi 45KW AC servo motor, ndipo kuzungulira kwa spindle kumayendetsedwa ndi lamba wolumikizana woyendetsedwa ndi makina osinthira liwiro.Liwiro osiyanasiyana ndi 3-1000r/mphindi, 4 magiya, hayidiroliki basi kusuntha stepless liwiro lamulo.Kusankhidwa kwa liwiro lozungulira kungadziwike molingana ndi zinthu monga zida zogwirira ntchito, kuuma, chida chodulira komanso kuswa chip.Malinga ndi liwiro losiyana, imatha kukhazikitsidwa kudzera mu pulogalamu yowongolera manambala, ndipo ma spindle bearings amasankhidwa kuchokera kumitundu yochokera kunja monga N SK ku Japan.Ntchito yayikulu ya bokosi lotopetsa la bar ndikuyendetsa chida kuti chizizungulira

3. Njira Yopangira Mafuta

Ili m'katikati mwa chida cha makina.Ntchito zazikulu za gawo lolandila mafuta ndi: 1. Lowetsani choziziritsa kukhosi.Chachiwiri, thandizirani bar yotopetsa kuti muchepetse kugwedezeka kwa chida chothandizira pakukonza.Chachitatu, kutsogolo kutsogolo kwa oiler kumakhala ndi chida chowongolera chida pamwamba pa chogwirira ntchito, chomwe chimatha kuzindikira chiwongolero cha khomo pomwe chida chopukutira chikukonzedwa.Chachinayi, wolandila mafuta atayikidwa pa bedi la bedi, amakankhira chogwirira ntchito pogwiritsa ntchito makina obwezeretsa mafuta, ndipo molumikizana amasewera ndi kukanikiza ndikusindikiza kumapeto kwa chogwirira ntchito komanso kudzidalira.Manja owongolera ndi chulucho amafunikira kuumitsa, ndipo kulimba kumafunika kukhala pamwamba pa HRC45.

4. Mafuta Otolera System

Ili kumapeto kumanzere kwa chida cha makina, imatha kuyenda motsatira njira ya axial ya thupi la bedi ndikukhazikika pamalo.Ntchito yaikulu ya chipangizo chobwezera mafuta ndi: nkhope yomaliza imakanizidwa motsutsana ndi workpiece kuti izindikire malo apakati a workpiece ndi mapeto a nkhope amasindikiza choziziritsa kuzizira kuti madzi odulira asagwedezeke;Kuphatikiza apo, madzi odulirawo amakulungidwa ndi tchipisi panthawi yopanga makina, ndikudutsa mu dzenje lamkati la chipangizo chobwezera mafuta kudzera mu chubu chotulutsa chip.Gawo lapansi la thupi lobwereranso la mafuta limalumikizidwa ndi chotchinga chooneka ngati T pakati pa bedi, ndipo kuyenda kwa axial kumazindikira kuyimitsidwa kwa chogwirira ntchito panthawi yokonza;ili ndi servo motor jacking device (chifukwa jacking imatenga servo motor jacking yapamwamba kwambiri, yomwe imalowa m'malo mwa The hydraulic jacking method imathandizira kusintha kwa mphamvu ya jacking kuti izindikire kulamulira kwa digito. osiyana, ndi mphamvu zosiyanasiyana jacking amasankhidwa kupewa nozzle deforming mpaka malire pazipita. ), kuzindikira centering ndi kusindikiza workpiece kukonzedwa , Kuuma kwa chimbale chunu chimbale chofunika kukhala pamwamba HRC45, ndi coaxiality pakati pa pamwamba chimbale ndi kutsogolo chimbale pamwamba pa mpando kukanikiza ndi zosakwana 0.05mm.

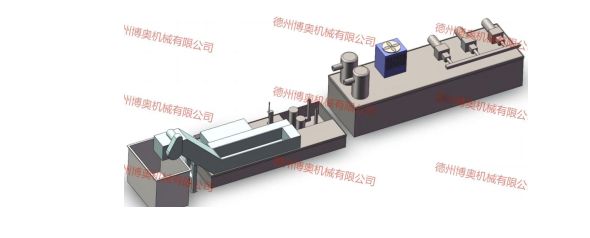

4. Makina Odyetsa Makina

Taiwan Shangyin mkulu-mwatsatanetsatane mpira wononga peyala waikidwa pakati ndi kumbuyo theka la poyambira wa makina chida thupi, ndipo pali bokosi chakudya kumapeto, moyendetsedwa ndi 5.5KW AC servo motor, kuzindikira kudyetsedwa kwa chida ndi mphasa chakudya (boring bar bokosi).Kuthamanga kwa chakudya kumatha kusinthidwa mopanda malire, ndipo chidacho chikhoza kubwezeredwa mwachangu.Theka lakutsogolo la poyambira la bedi la makina lili ndi chomangira chooneka ngati T ndi bokosi la chakudya, lomwe limagwiritsidwa ntchito kudyetsa chipangizo chobwezera mafuta, kusintha malo ogwirira ntchito ndi kukakamiza.Dongosolo lonse lodyera lili ndi ubwino wolondola kwambiri, kusasunthika kwabwino, kuyenda kosalala, komanso kusunga bwino.

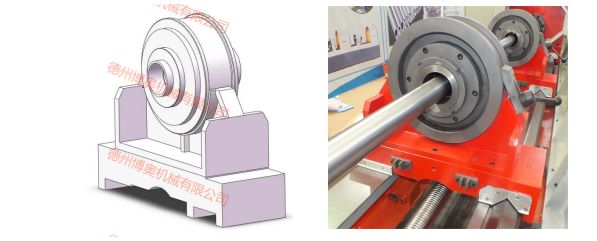

5. Boring Bar Support System

Mkono wothandizira wa bar wotopetsa umakhazikika pa bulaketi ndi zomangira, ndipo amasinthidwa pamodzi ndi bala yotopetsa, yomwe ili yabwino komanso yofulumira kusintha mipiringidzo yosiyanasiyana yotopetsa.Imakhala makamaka ndi gawo lothandizira bala yotopetsa, kuwongolera komwe kumayenda kwa bala yotopetsa, ndikuyamwa kugwedezeka kwa bar yotopetsa.Chombo chothandizira chamkati chokhala ndi ntchito yozungulira.

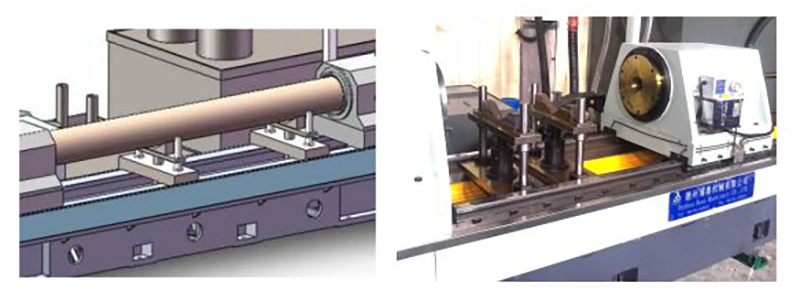

6. Workpiece Fixture Support System

Wokhala ndi ma seti awiri a block block yooneka ngati V kuti athandizire chogwirira ntchito.Zomangira ndi kukweza nati zitha kusinthidwa mosasamala malinga ndi ma diameter osiyanasiyana.Iwo makamaka amasewera workpiece katundu katundu ndi kusintha, ndi udindo wa dzenje wotopetsa

7. Hydraulic System

Chida cha makinacho chimakhala ndi makina apadera a hydraulic, omwe amagwiritsidwa ntchito kuwongolera kukulitsa ndi kutsika kwa chida cha hydraulic ndi kusuntha kwamadzimadzi kwa hydraulic kwa bokosi lotopetsa la bar kuti amalize dongosolo lowongolera.Kuthamanga kwake ndi 7Mpa.Zigawo zazikuluzikulu ndizochokera kunja kwa kafukufuku wamafuta.

8. Woziziritsa Zosefera System

Kuzizira kwa chip kuchotsa ndi kusefera: makamaka yomwe ili kumbuyo kwa chida cha makina, mutatha kusefa ndi makina a chain plate automatic chip kuchotsa (coarse fyuluta)→sefa yamafuta yoyamba →sefa yamafuta ya mulingo wachiwiri ndi kusefera kwachitatu pambuyo pothira madzi ndi kusefera.Zitsulo zachitsulo zimatumizidwa ku galimoto yosungiramo tchipisi ndi chotengera cha chain plate chip, choziziritsira chimabwerera ku tanki yamafuta, kenako choziziritsira chimaperekedwa kwa wolandila mafuta kudzera popopera kozizirira, ndipo mafutawo amaperekedwa ndi seti 3. mapampu a vane kuti akwaniritse zosowa zosiyanasiyana za kukula kwa dzenje la workpiece.

Mukakonza dzenje lamkati la chogwirira ntchito, tsinde lalikulu la bokosi lotopetsa limayendetsa chidacho kuti chizungulire, ndipo tchipisi tachitsulo timanyamulidwa ndi choziziritsa kukhosi ndikutulutsidwa kudzera mu dzenje lamkati la chipangizo chobwezera mafuta.Makina ochotsa tchipisi odzichitira okha amatumiza tchipisi tachitsulo kugalimoto yosungiramo tchipisi, ndipo choziziritsira chimasonkhanitsidwa ndikubwezeretsedwanso.

9. Kugwiritsa Ntchito Makina

Makina owongolera opangira zida zamakina amayikidwa pampando wopondereza ndikukhazikika papampando wapampando, womwe ndi wosavuta kugwiritsa ntchito chida cha makina.Gululo limapangidwa ndi chitsulo chosapanga dzimbiri cha matt, mawonekedwe ake amalumikizana, okongola komanso olimba.

Pulogalamu yamakina idapangidwa ku Siemens ndipo imagwiritsidwa ntchito kwa zaka zambiri.Timapita patsogolo ngati mulingo wapadziko lonse lapansi.

10.Electric System

Amakhala ndi main control box, opareshoni box, terminal box ndi zingwe.Zida zazikulu zamagetsi ndi mtundu wa Schneider.Kwa bokosi lowongolera magetsi (kuzizira kwa mpweya).Gawo lalikulu la mawaya limatengera kapangidwe ka pulagi ya ndege.Zingwezo zimatengera muyezo wadziko lonse, ndipo zingwe zofooka zapano zimatenga zingwe zotetezedwa.Mawaya amakonzedwa mosamalitsa molingana ndi kudzipatula kwamphamvu komanso kofooka kwamagetsi.

| NO | Zinthu | Mitundu | NO | Zinthu | Mitundu |

| 1 | Thupi lachitsulo la makina | Chodzipangira | 2 | Boring bar drive box | Chodzipangira |

| 3 | Thandizo gulu | Chodzipangira | 4 | Kunyamula spindle | Japan NSK |

| 5 | Zimbalangondo zina | Mitundu yabwino | 6 | Mpira konda | Mtundu waku Taiwan |

| 7 | Zinthu zazikulu zamagetsi | schneider kapena siemens | 8 | Spindle motor | China mtundu |

| 9 | Dyetsani servo mota | Siemens | 10 | Dyetsani woyendetsa servo | Siemens |

| 11 | CNC ndondomeko | Siemens | 12 | Pneumatic zinthu | Japan SMC |

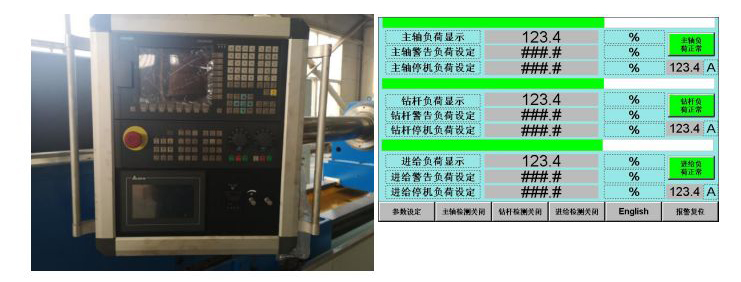

10.CNC Control System

Chida cha makina chili ndi dongosolo la SIMENS828D CNC, ndipo kupanikizika kozizira kumawonetsedwa ndi zida.Galimoto ya chakudya ndi mota ya servo, ndipo galimoto yotopetsa yamabokosi imatumizidwa kunja.Kudyetsa pamanja, kudzidziwitsa nokha ntchito.Chiwonetsero cha Status,

Ntchito zosiyanasiyana monga mawonedwe apano a malo, mawonedwe a pulogalamu, mawonedwe a parameter, mawonetseredwe a alamu, kutembenuza zinenero zambiri, ndi zina zotero. Ndi mawonekedwe a RS232 / USB, akhoza kukonzedwa kunja kwa makina.Okonzeka ndi pulogalamu athandizira ndi linanena bungwe mawonekedwe, amene akhoza kutaya ndi kusungidwa pa kompyuta.Konzani gulu lalikulu loyang'anira ndi siteshoni ya batani la ntchito, mawonekedwe a ntchito ya ku China ndi masinthidwe ogwiritsira ntchito, mabatani, ndi zina zotero. Chiwonetsero chachikulu chowongolera chithunzi cha man-machine chimagwiritsidwa ntchito poyang'anira momwe zida, zowonetsera zolakwika ndi zina zowongolera.Ndi kudzizindikira, ntchito yodziteteza, yokhala ndi chiwonetsero cha LCD.

Kuphatikiza apo, gawo lodzitchinjiriza la chida limayikidwa: Taiwan Delta PLC + man-machine dialogue touch screen imagwiritsidwa ntchito kuyang'anira chida chomwe chikuyenda munthawi yeniyeni.Pamene chida kuthamanga kuposa preset mtengo wa boma yachibadwa pasadakhale, chitetezo chida chida makina adzakhala alamu mu magawo awiri mwamsanga kapena kusiya basi, ndipo akhoza mwachidziwitso kuona akuthamanga udindo wa kusuntha mbali ya makina chida, amene ali opindulitsa chitetezo cha kuwonongeka kwa zida ndi chitetezo cha workpiece processing.Kuyika kwa parameter ndikosavuta, mwachilengedwe, kosavuta komanso kodalirika.Pulogalamu yachitetezo cha chida cha PLC imawonjezedwa kuti mupewe zochitika za "kutsekera zida".